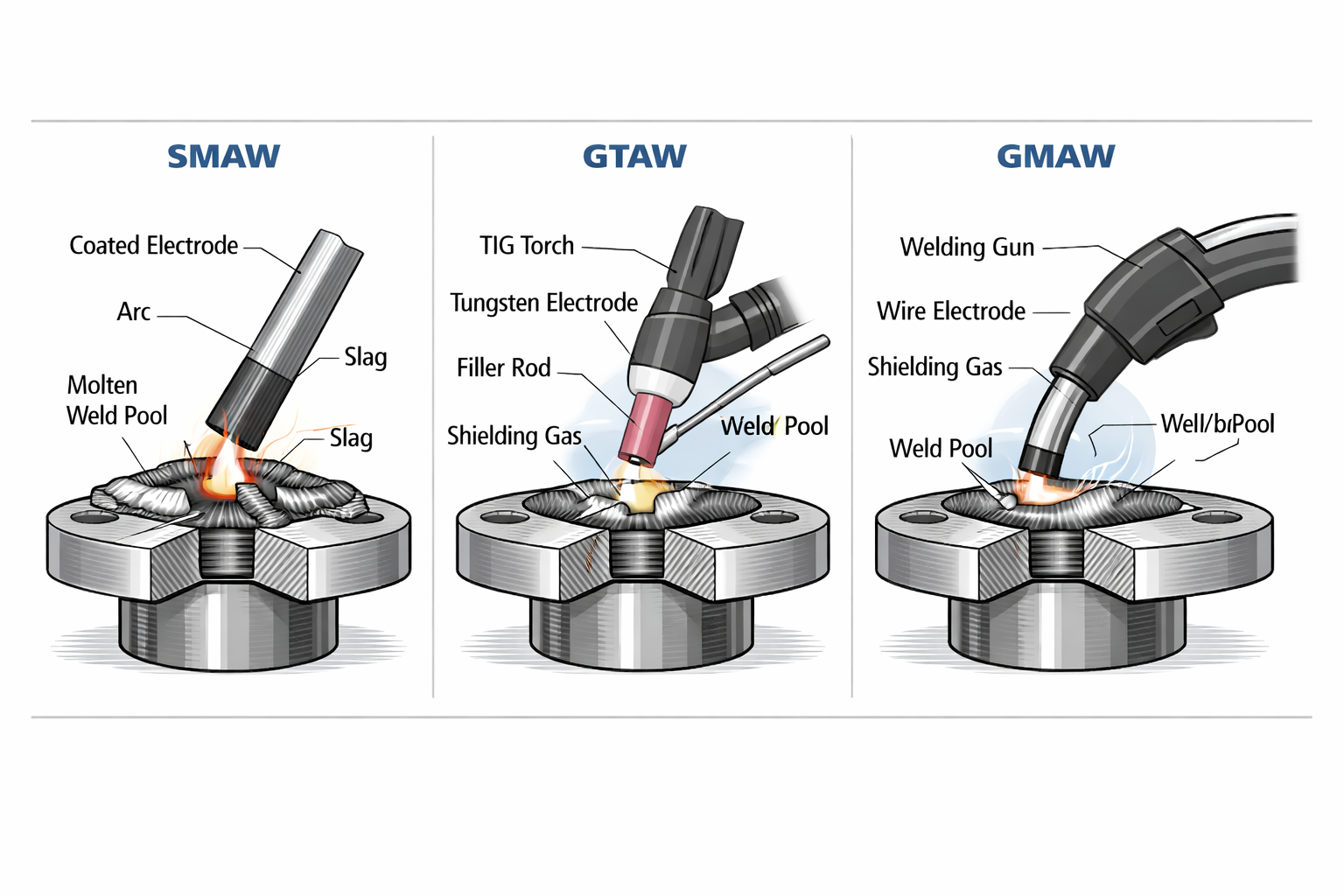

Welding is how you permanently join a flange to a pipe. The type of weld matters for strength, safety, and cost. This article explains the three main methods: SMAW, GTAW, and GMAW.

Picking the right method affects everything. It changes the weld’s quality, how fast you can work, and where you can do the job. We will explain how each process works and where to use it.

Table of Contents

Why the Welding Process Matters for Flanges

A flange connection must be strong and leak-proof. It handles pressure, heat, and sometimes chemicals. A bad weld can fail. The welding method changes:

- Weld Strength: How well it handles stress and fatigue.

- Seal Quality: Preventing leaks at the joint.

- Material Compatibility: Some methods work better on certain metals.

- Cost & Speed: Labor time and equipment costs vary.

- Worksite Needs: Can you work in a shop, or do you need to weld in the field?

Method 1: SMAW (Shielded Metal Arc Welding) – “Stick Welding”

How it works: SMAW uses a consumable electrode (the “stick”). This rod has a metal core and a flux coating. The welder strikes an arc between the rod and the workpiece. The heat melts the rod’s core and the base metal, creating the weld. The flux coating melts too. It creates a gas shield and a layer of slag to protect the molten weld.

Best for Flanges:

- Field work and construction sites. The equipment is simple, portable, and rugged.

- Thicker carbon steel flanges.

- Outdoor welding. It is less sensitive to wind than gas-shielded processes.

- Maintenance and repair work.

Pros:

- Low-cost, simple equipment.

- Very portable. All you need is a machine, leads, and rods.

- Works well on rusty or painted metal (with proper cleaning).

- Effective outdoors.

Cons:

- Slower than wire-fed processes.

- Requires stopping to change rods, which can interrupt the weld.

- Produces slag that must be chipped off after welding.

- Can be harder to make very clean, precise welds on thin material.

Method 2: GTAW (Gas Tungsten Arc Welding) – “TIG Welding”

How it works: GTAW uses a non-consumable tungsten electrode to create the arc. A separate filler rod is added by hand. An inert gas (like argon) flows from the torch to shield the weld area from air. This prevents contamination.

Best for Flanges:

- Critical, code-quality welds (e.g., in power plants, chemical processing).

- Stainless steel and alloy steel flanges.

- Thin-walled pipes and small-diameter flanges.

- Situations where weld appearance and precision are top priorities.

Pros:

- Produces the highest quality, cleanest welds with excellent appearance.

- Great control over heat input, reducing warping on thin flanges.

- No spatter or slag.

- Best for welding exotic metals.

Cons:

- Requires the highest level of welder skill.

- The slowest of the three processes.

- Sensitive to drafts, dirt, and contamination. Needs a clean work area.

- More expensive equipment.

Method 3: GMAW (Gas Metal Arc Welding) – “MIG Welding”

How it works: GMAW uses a wire feeder to push a continuous, consumable wire electrode to the torch. The wire melts into the weld. A shielding gas (like argon/CO2 mix) flows from the torch to protect the weld pool.

Best for Flanges:

- Shop or factory production where speed is important.

- Semi-automatic welding of carbon steel flanges.

- Medium-thickness materials.

- Situations where a good balance of quality and speed is needed.

Pros:

- Fast deposition rate. You can lay down more weld metal, faster.

- Easier to learn than GTAW.

- Continuous wire feed means fewer stops and starts.

- Clean process with little post-weld cleanup.

Cons:

- Less portable than SMAW due to the wire feeder and gas bottle.

- Not ideal for very thick sections or all positions (depending on mode).

- Sensitive to wind and drafts outdoors.

- Equipment is more complex and costly than SMAW.

Comparison of Flange Welding Methods

This table helps you see the key differences at a glance.

| Formal Name | Shielded Metal Arc Welding | Gas Tungsten Arc Welding | Gas Metal Arc Welding |

| Skill Required | Medium | Very High | Low to Medium |

| Typical Speed | Slow | Very Slow | Fast |

| Weld Quality | Good | Excellent | Very Good |

| Best Environment | Outdoors, Field | Indoors, Shop | Indoors, Shop |

| Equipment Cost | Low | High | Medium |

| Key Flange Uses | Field repair, structural, heavy carbon steel. | Process piping, stainless, thin-wall, code work. | Production work, general fabrication. |

Note: For more info checkout more useful info “How to Weld a Flange to a Pipe: A Complete Guide“.

How to Choose the Right Welding Method

Here are the main questions to ask when choosing a method for a flange job:

1. What is the flange material?

- Carbon Steel: All three methods work. Choose based on other factors.

- Stainless Steel/Alley: GTAW is best for critical joints. SMAW and GMAW can be used with specific filler metals.

- Exotic Alloys: Typically require GTAW.

2. What are the job conditions?

- In a controlled shop? GMAW or GTAW.

- Outdoors on a pipeline? SMAW.

- Need the highest possible quality? GTAW.

3. What is the wall thickness?

- Thin-walled pipe: GTAW gives the best control to avoid burn-through.

- Very thick sections: SMAW or GMAW may be more efficient for filling the joint.

4. What is the budget and skill level?

- Limited budget, basic skill: SMAW or GMAW.

- High-skill welder available, quality is key: GTAW.

Common Flange Welding Issues and Solutions

Problem: Weld cracks.

- Cause: High stress, wrong filler metal, or hydrogen in the weld (from moisture).

- Fix: Use low-hydrogen rods (SMAW), ensure perfect filler metal match (GTAW/GMAW), pre-heat thick material.

Problem: Warping or distortion of the flange.

- Cause: Too much concentrated heat.

- Fix: Use a lower heat input process like GTAW. Use “tack and stitch” technique: weld a little, skip to the opposite side, let it cool.

Problem: Porosity (holes in the weld).

- Cause: Contamination (oil, rust, moisture) or loss of gas shield.

- Fix: Clean the joint perfectly. For GTAW/GMAW, check gas flow and protect from wind.

Problem: Lack of fusion (weld doesn’t stick to base metal).

- Cause: Not enough heat or wrong technique.

- Fix: Increase amperage. Ensure proper weld groove preparation and arc placement.

FAQs – Frequently Asked Questions

1. Which method is strongest for a flange weld?

The strength depends more on proper procedure, fit-up, and welder skill than the method itself. A correct weld made by any of these processes can be “full strength,” meaning as strong as the pipe and flange.

2. Can I use GMAW (MIG) to weld stainless steel flanges?

Yes, but it is less common for critical pipe welds. You must use a tri-mix shielding gas (argon/CO2/helium) and stainless wire. GTAW is still preferred for its superior control and quality on stainless.

3. Why is SMAW so common in construction?

Its portability and tolerance for less-than-ideal conditions make it perfect for field work. You don’t need to carry gas bottles, and a little wind won’t ruin the weld.

4. What is “back purging” and when is it needed?

Back purging means flowing inert gas (argon) inside the pipe while you weld. It is needed when using GTAW or GMAW on stainless steel or alloys. It prevents “sugaring” – a rough, oxidized weld on the inside that is weak and can corrode.

5. Is GTAW worth the extra time and cost?

For critical systems—like those carrying steam, chemicals, or high pressure—yes. The superior weld integrity and corrosion resistance justify the cost. For non-critical supports or water lines, it may be overkill.

6. Do I need special certification to weld flanges?

Often, yes. Many projects require welders to be “code-qualified” to a standard like ASME Section IX. This proves they can produce a sound weld with a specific process and material.

Conclusion

There is no single “best” welding method for all flanges. The right choice is a practical one.

- Use SMAW for its toughness and portability in the field.

- Use GTAW for top quality on critical, clean, or thin materials.

- Use GMAW for efficient, quality work in a shop setting.

The goal is a leak-proof, strong connection that meets the project’s requirements. Matching the process to the material, environment, and skill level is the key to a good flange weld. Learn More about Flanges here: Texas Flange